The end result will provide novel ideas that advance development and marketing of the SOLSA Expert System

Solvers = students developing solutions (sought by the seekers)

Seekers = organizations facing innovation problems and seeking solutions

Read more about the outcomes of these “problem-solving” activities and WHICH IS THE WINNING TEAM...

A win-win situation

The three challenges explore innovative solutions in the field of the mining industry, having a direct link to and impact on the SOLSA Expert system. The students were put to the test and developed competence in solving industrial problems and challenges (Challenge-Based Learning), whereas their mentors (teachers, researchers and Project Participants) disseminated and transferred their knowledge and technological know-how.

Participating teams from various universities presented their solutions to a jury and had their idea scored based on the innovativeness and potential business impact.

All Solvers will receive a certificate of participation and will have the possibility of gaining recognised F-type ECTS credits

"The SOLSA challenge gave us the opportunity to work on a project that could make a tangible impact on a real company's operations while also fulfilling our student project requirements"

Discover the three Challenges and their outcomes

Challenge 1 - Intelligent Core Drill Characterization MODULAB

Solvers

Élouan Froissart, Joseph Frizon de Lamotte, Valentin Ogé

Owner and Mentors

University of Trento

©

Rise to the challenge

Develop an intelligent exploitation of the material features provided by the drilling equipment, as concerns in particular the mechanical properties and core drill constituents. The pin pointed usage of this information may provide important guidelines to the core handling and for its effective characterization.

Sonic Rig in action during a geological exploration project with the operational team recovering fresh drilled samples

© Royal Eijkelkamp

Summary

This study explored innovative ideas that can be used to combine efficiently geotechnical and mineralogical data. The objective was to link these parameters to Crystallographic databases to obtain geological interpretation as fast as possible for an automatic treatment considering any specification of the area of interest (e.g., weathering, faulting…).

The project developed the effective exploitation of the combined analysis method and the usage of adequate databases, to be selected based on the specific geomorphological features of the customer's site. An additional factor, which may profitably be integrated into the SOLSA analytical architecture, is the intelligent exploitation of the material features provided by the drilling equipment, as concerns in particular the mechanical properties and drill core constituents. The pinpointed usage of this information may provide important guidelines for core handling and for its effective characterization.

As it was not possible to test the model during development on real data, the next step would be to test manually each step on real data to upgrade the model, build corresponding databases and automate their operation. This could open new prospects for SOLSA, from mining exploration to environmental monitoring.

Challenge 2 - Conception of a high-impact marketing tool for the SOLSA MODULAB

Solvers

Jade Din, Jeremy Mompelat, Mahé Auch-Roy

Owner and Mentors

Owner and Mentors

©

Rise to the Challenge

Develop a digital marketing campaign with the objective to reach the most appropriate, high-impact tool and develop a roadmap, including expertise required, typical subcontractors, scenario and recommendations.

View of the SOLSA MODULAB 360° Virtual Tour. One can freely navigate inside and outside, and press the buttons for more information and explanatory videos

© BRGM

Summary

After a first stage of enhancing our understanding of the MODULAB and its Unique Value Proposition (UVP), which involved interaction with the BRGM and Inel Innov team, we conducted an analysis of its current position on the market and the needs for a high-impact tool.

We prioritised and developed a 360° virtual tour of the MODULAB to provide a more informative, visual, and interesting way to inform potential new clients about the product and its value proposition on a global scale. By offering a unique and memorable experience and by fostering engagement, understanding, and visualization, this marketing tool plays a pivotal role in transforming potential customers from mere consideration to conversion. Finally, the 360° virtual tour not only showcases SOLSA-DEM’UP’s and Inel Innov’s commitment to innovation, but also delivers a compelling and memorable presentation that sets the Modulab apart from competitors relying solely on conventional marketing methods.

Finally, the carefully selected strategy was built in response to Inel Innov’s needs including the potential business impact of our proposed solution and how this marketing tool could help SOLSA and Inel Innov achieve their business objectives in the medium to long term.

Challenge 3 - GeoWhileDrilling – Rock Classification. Intelligent core drill characterization

Solvers

Theophile Cholet, Robin Fort, Lucas Granger, Theo Royer

Owner and Mentors

Owner and Mentors

©

Rise to the Challenge

Develop correlation between MWD (measurement while drilling) information and rock properties (lithology + geotechnical), including proposal to validate these findings + validation of theoretical model and development of in-situ empirical model.

Summary

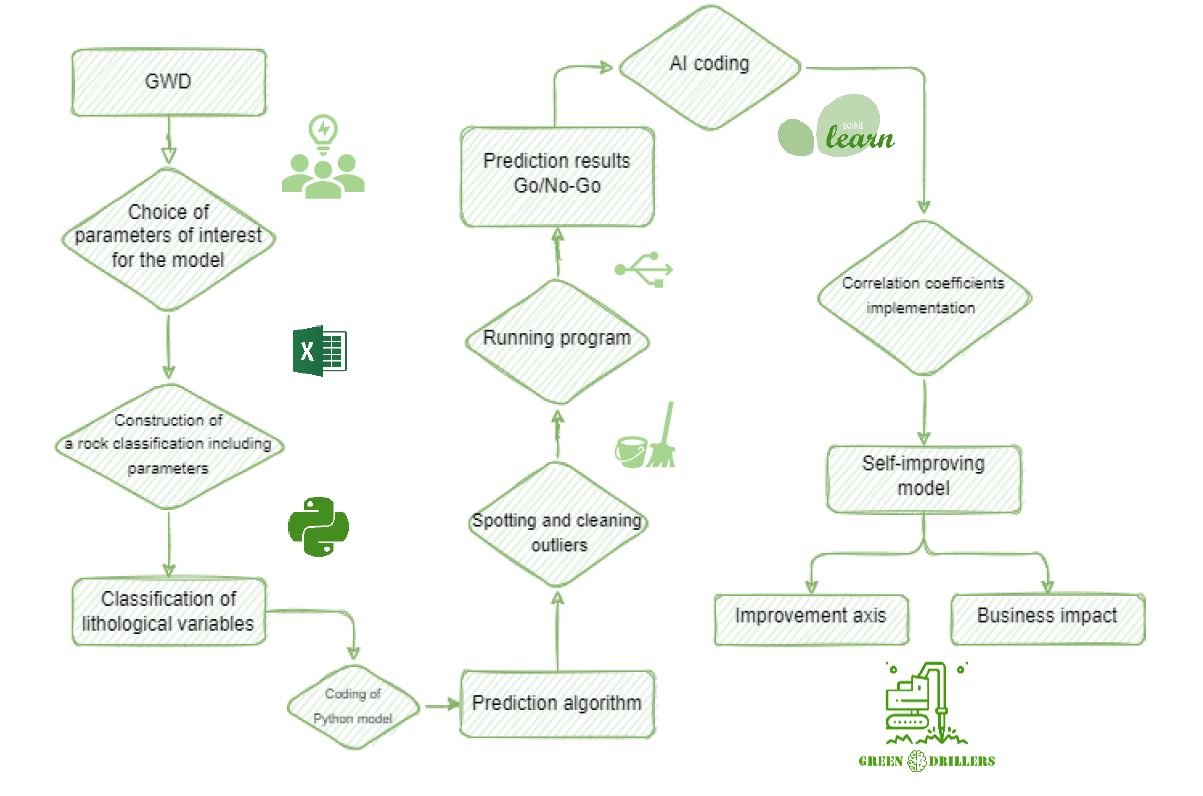

In this challenge, a theoretical predictive model was developed to highlight the links between sonic drill performance measurements, and the lithological and geotechnical properties of the rock formations drilled. Datasets from the SOLSA 1 project in 2018 and 2019 were used to test the geological prediction Python model based on correlations of 6 custom parameters. The calculation of the relative error was added to the model.

A comparative classification has been created by the Green Drillers team to establish a ranking of Geotechnics while drilling (GWD) measured features. These different parameters are quantified in various units, so they have been weighted on a new common scale for relative comparison with each other. After several unsuccessful attempts, a highly relevant range classification has been chosen for crossing the selected features with superior efficiency and simplicity of understanding.

The theoretical lithological prediction model implemented for this challenge is already operational, taking 6 verified parameters into consideration. Artificial intelligence applications have also been identified. To extend the prediction possibilities, other sonic probes can be implemented on the survey as part of the next technological steps. Well logging combination could provide complementary information for features like Gammay-Ray, that can ensure the clay identification. Integration of “fullwave” sonic imagery could also confirm the presence and direction of fractures and unconformities, as presented below.

Method and principle of the approach

© Green Drillers

Congratulations to the winning team

-

Challenge no. 3 launched and mentored by SOLSA partner Royal Eijkelkamp

-

Theophile Cholet, Robin Fort, Lucas Granger, Theo Royer from the French University UniLaSalle

The chosen topic "GeoWhileDrilling - Rock Classification" is based on Eijkelkamp's new Monitoring While Drilling system, which is coming out soon. The team developed a theoretical predictive model to highlight the links between sonic drill performance measurements, and the lithological and geotechnical properties of the rock formations drilled. The solution leverages artificial intelligence for mineralogical analysis aimed at optimizing the identification of raw materials by developing a correlation between the information collected during mining drilling and rock properties. It will offer the advantage of on-site, real-time operation, reducing processing and analysis times and costs.

Winning Team - Challenge 3

©

The SOLSA Challenge team would like to congratulate all the solvers for the high quality of their reports, presentations and results.

"The theoretical model developed by the winning team puts Eijkelkamp another major step closer to our mission to maximize the productivity and efficiency of geological exploration while keeping the environmental and operational impact to a minimum"

This Open Innovation Challenge is organised by the SOLSA partner HIT (Fondazione Hub Innovazione Trentino) within the framework of the SOLSA-DEM'UP project and is based upon Knowledge Triangle integration. By involving activities in education, innovation and business creation and bringing people from the three sides of the Knowledge Triangle closer together, this enables the innovation that will help Europe flourish economically while growing sustainably.

HIT

©