This 5-day field diary is the opportunity to follow a drill core on it’s SOLSA journey from extraction through to sample analysis and then to visualizing the results.

Day 1 – overview and aims

Interview with Sylvain Delchini, SOLSA project manager at BRGM

So tell us a bit more about the SOLSA Expert System that is being tested here…

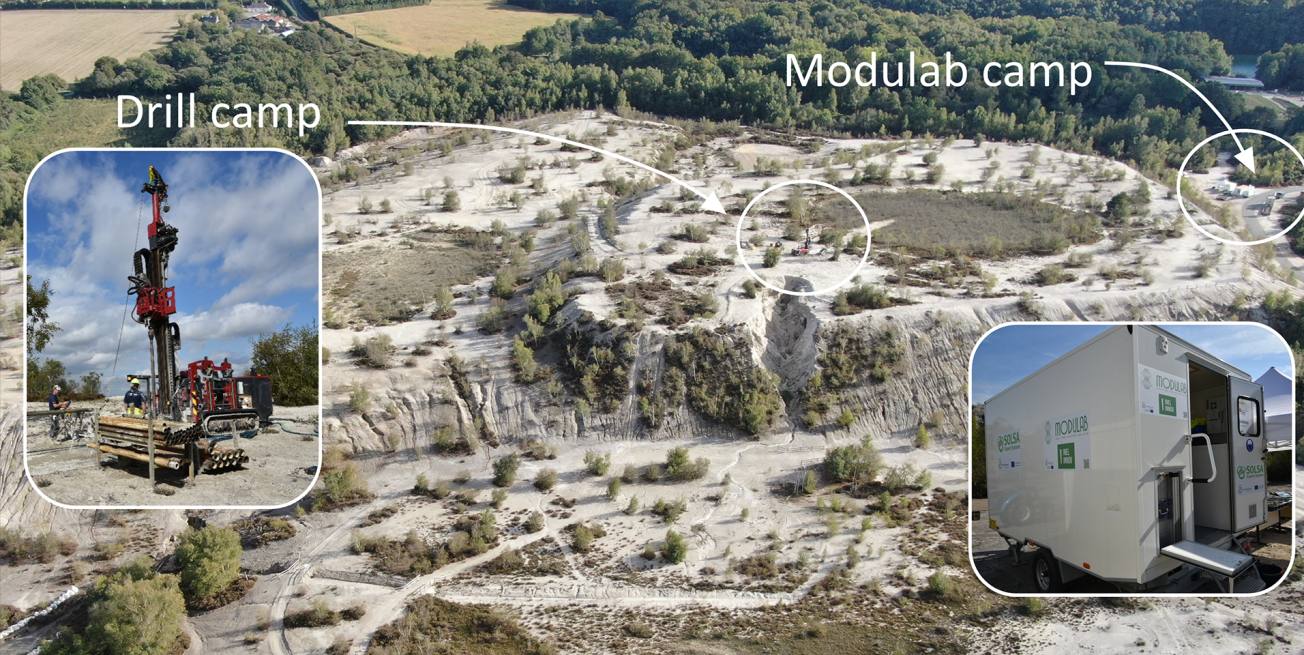

Basically, the system aims to fast-track core and sample analysis by bringing investigation capabilities on-site, exactly where they're needed, i.e. the equipment capable of extracting drill cores of potential interest and then directly analysing them. The system is made up of a combination of three modules and designed to work directly onsite. 1/ a mobile sonic drilling rig, to recover high quality rock cores, 2/ a mobile analytical laboratory (Modulab) where the rock samples are prepared an analysed (core scanner and benchtop analyser), all hooked up to 3/ a powerful software and database module that enables the morphological, chemical and mineralogical results obtained from the Modulab to be viewed on-site in real time.

Why do the tests here at Abbaretz?

The old Abbaretz tin mine is an ideal application case because of its mining history. Tin is believed to have been mined from the region since 1200 BC. The main deposit at Abbaretz was mined more recently in two periods: 1920-1926 (underground mining) and 1951-1957 (open-pit mining). So testing here not only provides a good case for a mining and exploration context, but also from an environmental perspective in terms of monitoring of the site by BRGM due to the presence of acid mine drainage.

The SOLSA Expert System aims to fast-track core and sample analysis by bringing investigation capabilities on-site, exactly where they're needed

Which partners were chosen for this project and why?

The Consortium of the SOLSA-DEM’UP project brings together companies from the mining sector (the Coordinator Eramet Ideas, France, and Eijkelkamp, The Netherlands), a geoscience national survey (BRGM, France), experts in industry-research-academic collaboration (HIT, Italy), software developers (University of Trento, Italy), and the start-up TerrAnalytiX who is developing and bringing to market the Modulab solution.

Day 1 slide show

Day 2 – sonic drilling

Interview with Daniel Julius from Eijkelkamp

What is Eijkelkamp’s role in the SOLSA-DEM’Up project and, more specifically, in these field tests?

Our main role in SOLSA is to deliver high-quality core samples, directly on site, so drilling accuracy and efficiency are our main goals. Here at Abbaretz, we will test the capacity of the sonic drill and we’ll be drilling several boreholes at varying depths. The field tests are the opportunity to begin the fine-tuning process of the MWD (Measurement While Drilling) in our sonic drilling rig, which is crucial in maximizing drilling effectiveness and reducing environmental impact.

Another specific goal here is to test our radar safety device on the drilling rig: ensuring the safety of our operations is paramount. It was put to the test, and the results are promising; its robust capability in ensuring secure and smooth drilling operations was demonstrated.

What exactly does sonic drilling mean and why use it?

The sonic drilling technology here has a vibration frequency of 150 Hertz (i.e. 150 vibrations per second). So, when penetrating the lithology, the outside of the drill string is under a fluidisation effect, which means less disturbance of the soil and easy penetration of soft-to-medium hard lithology. The result is efficient extraction of high-quality cores.

The result of the sonic drilling is the efficient extraction of high-quality cores

What are the advantages of the drilling module of the SOLSA Expert System compared to other standard drilling techniques?

The use of sonic drilling (rather than rotary) has the advantage of using less water, providing better quality samples and avoiding core loss (we have 100% recovery here). Another advantage is that the drilling rig is mobile, which means we can drill the regions identified as being of potential interest, even when remote. Providing the ground can take the weight of the drilling machine, it can travel anywhere mounted on a truck.

Day 2 slide show

Day 3 - combined analysis in the Modulab

Let’s discover more about the sample preparation and analysis stage.

Interview with Henry Pillière, CEO of the start-up TerrAnalytiX

Describe to us in a few sentences what the Modulab is

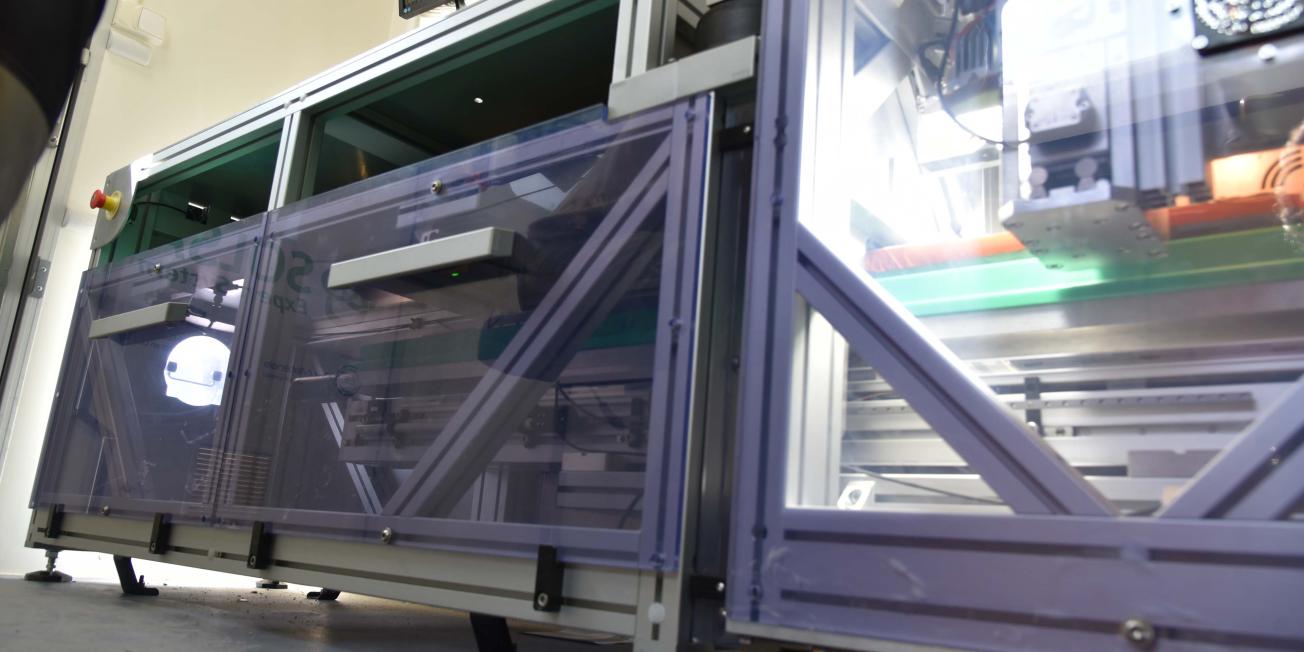

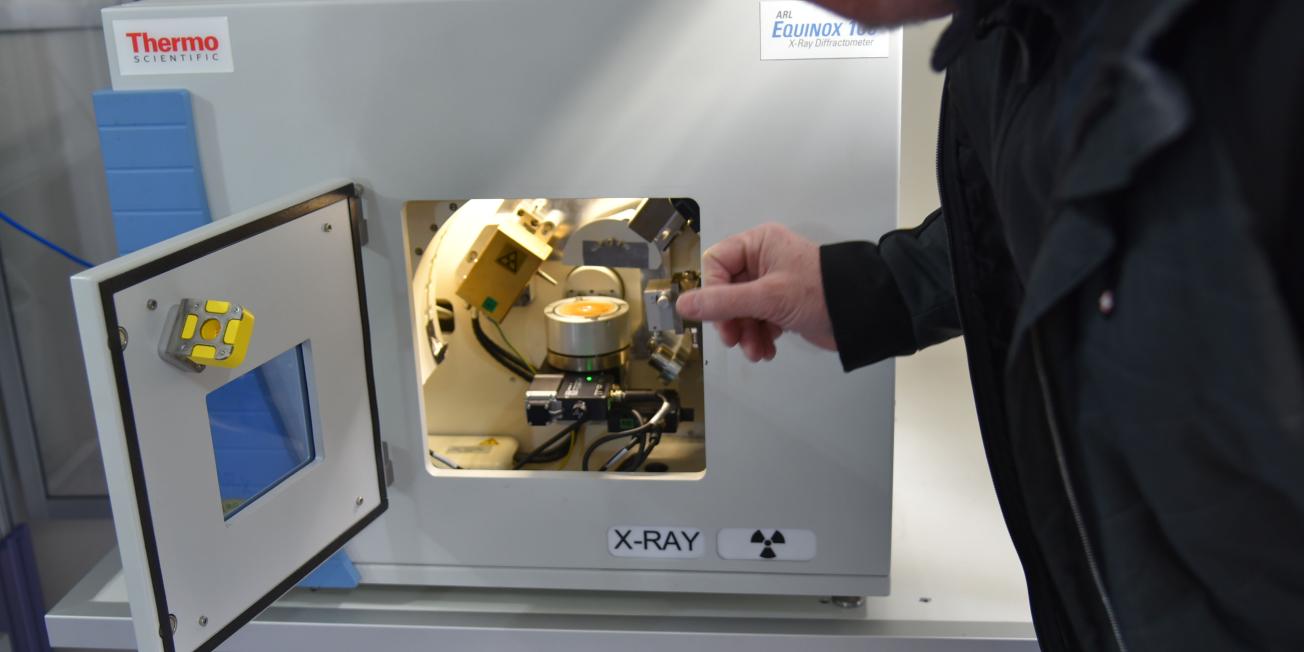

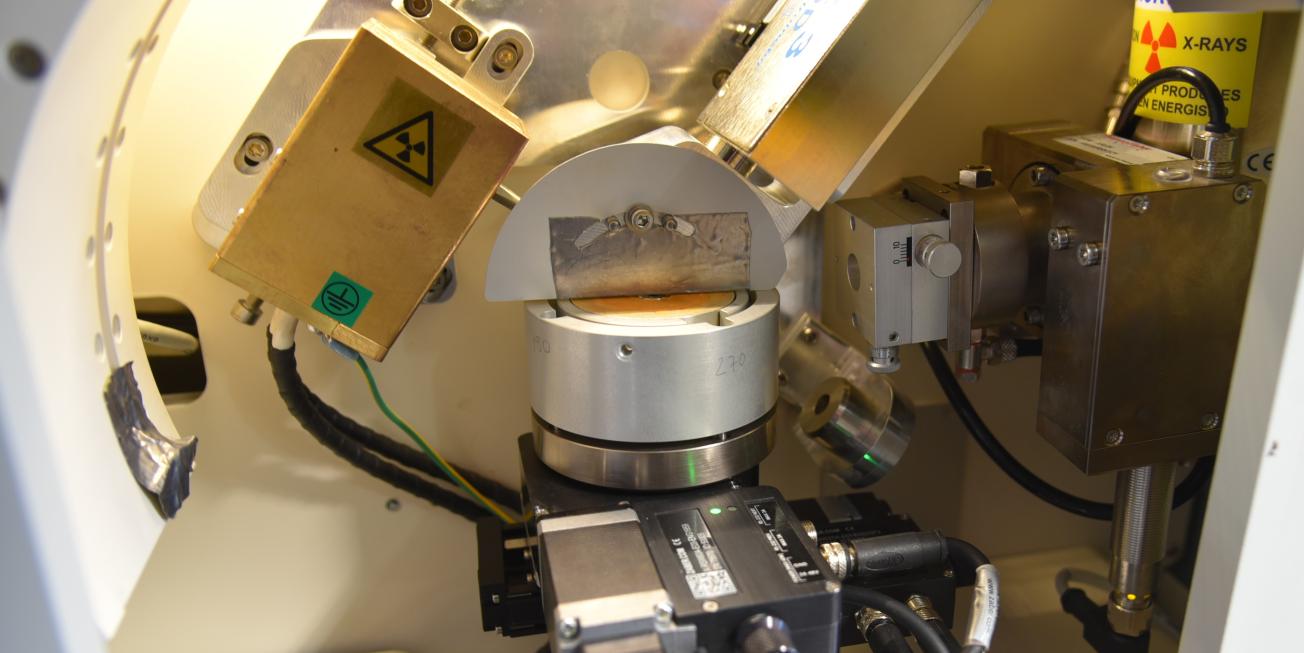

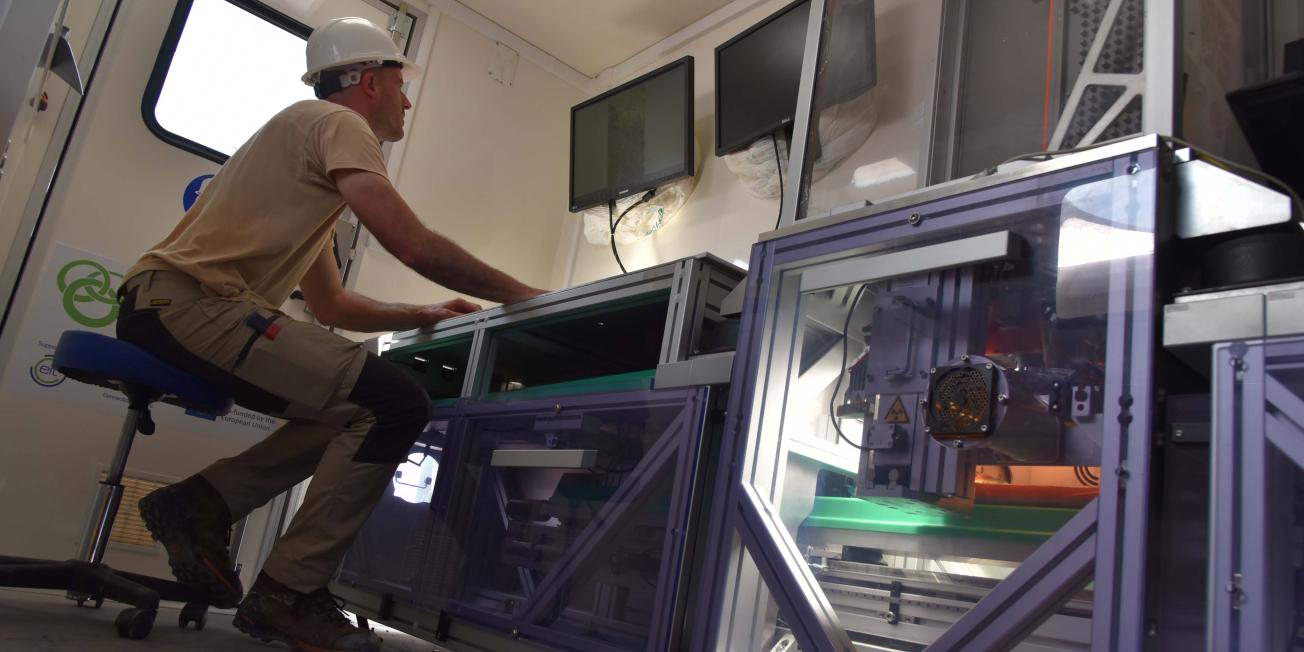

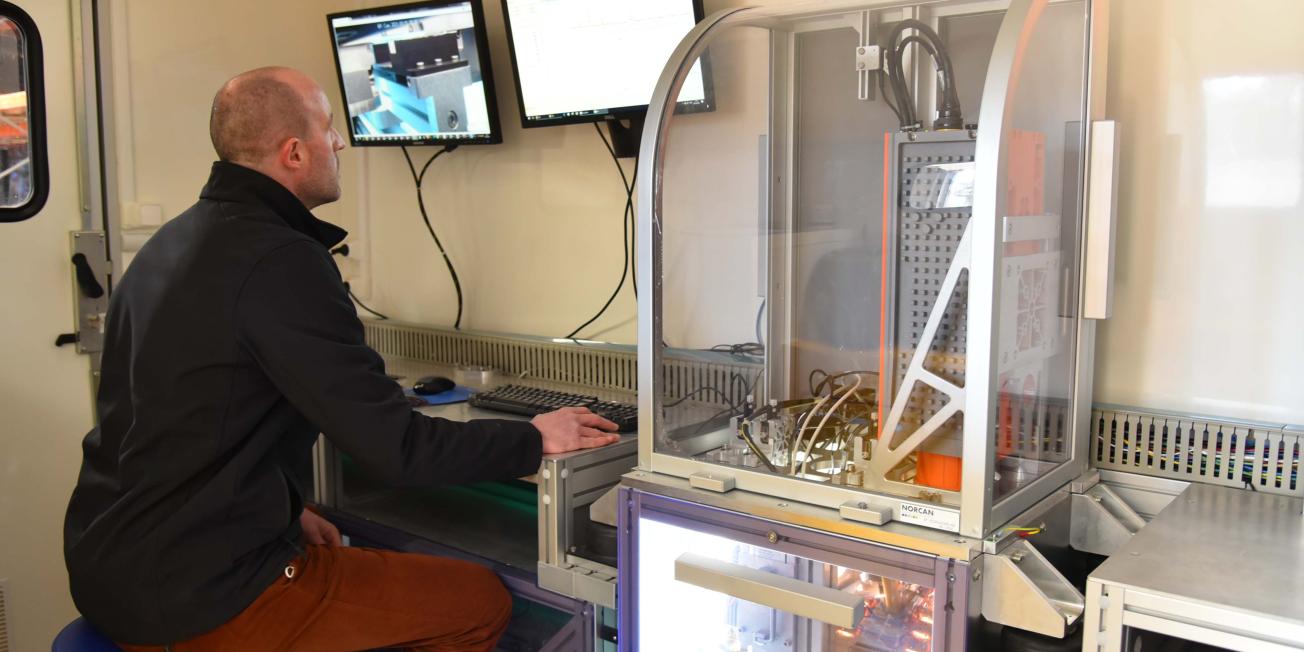

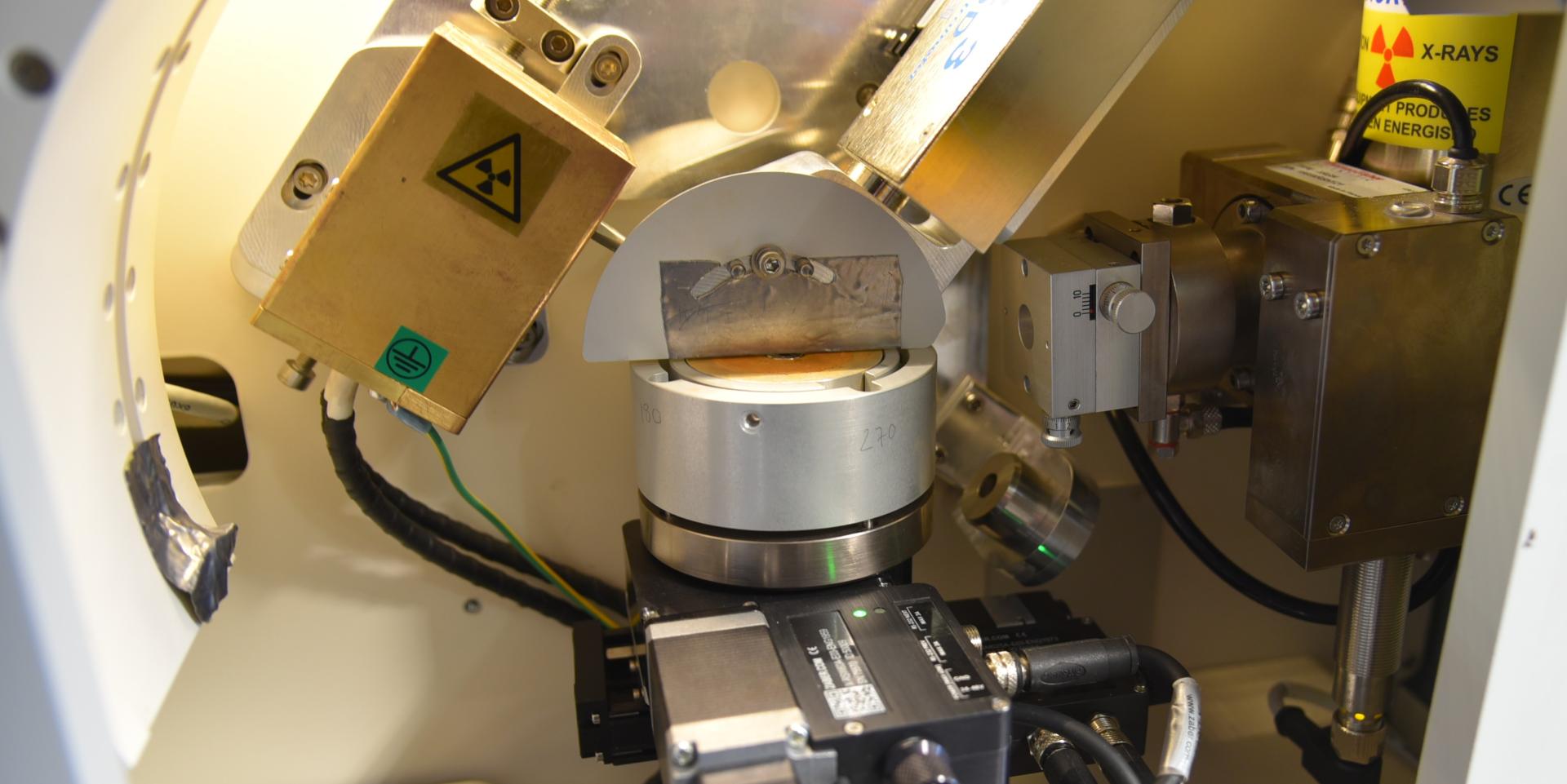

The Modulab is a mobile robotic field laboratory that enables real-time, on-site analysis of drill cores, rock chips or powders, in fact any form of sample, such as the loose material constituting the tailings here at Abbaretz. For this field test, it is equipped with a multi-sensor core scanner for continuous analyses (morphology, chemistry, mineralogy) and a benchtop analyser for discrete analyses (XRD and XRF chemistry, mineralogy). It is unique because it’s mobile, robust, has a low consumption, can analyse on site and the results are almost instantaneously available.

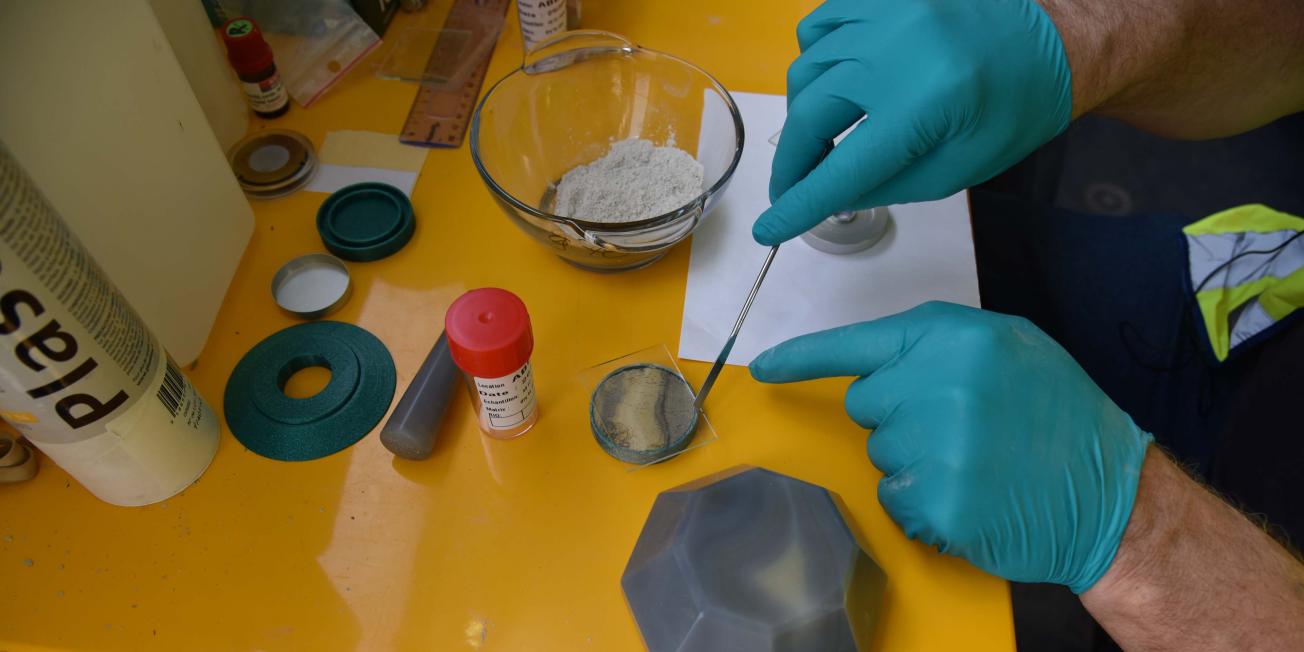

How’s the rock analysis done?

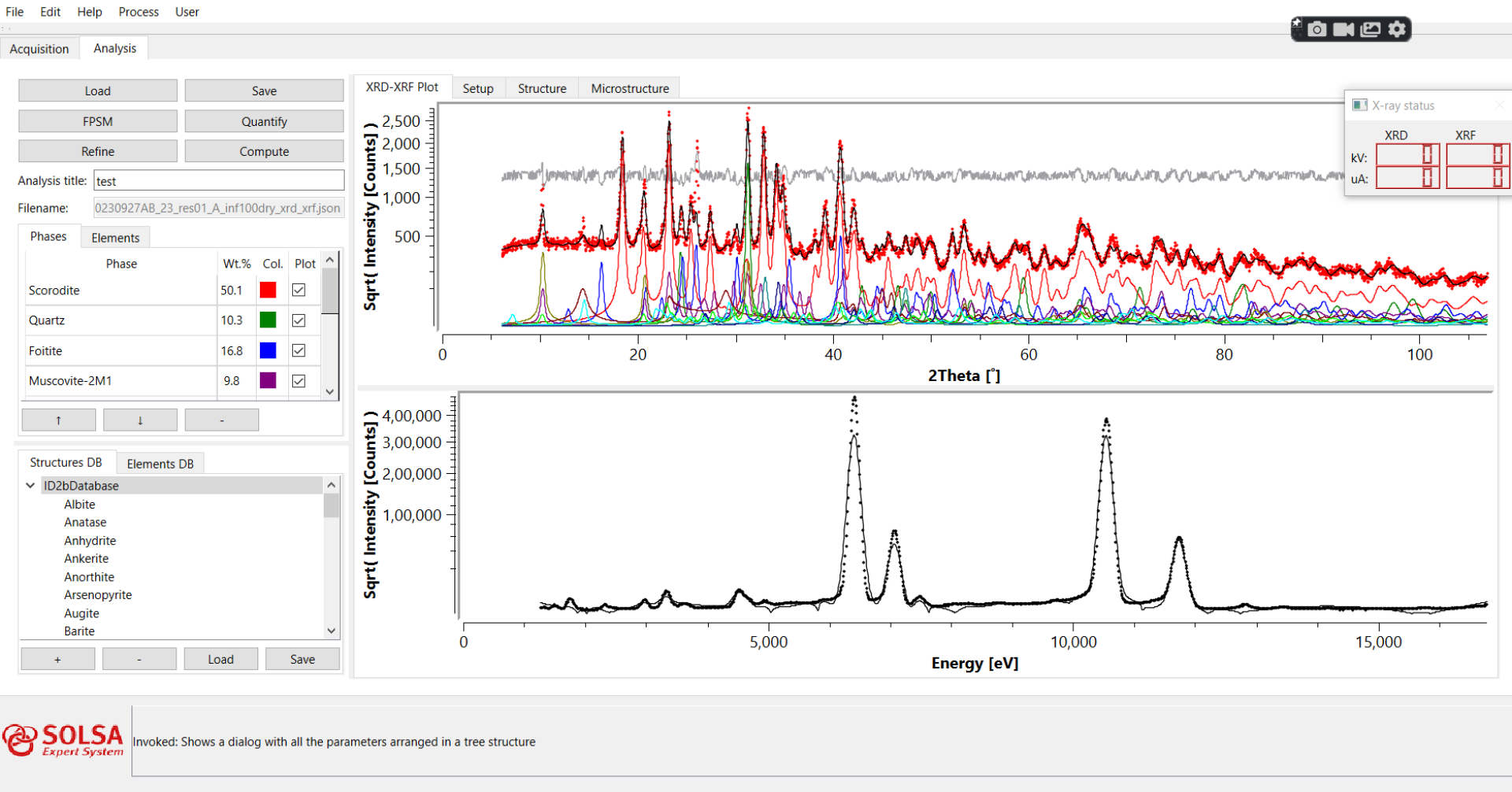

The cores are introduced via a trap at the rear of the Modulab onto a conveyor that feeds into the core scanner, where the instruments analyse the cores for their morphology, chemistry and mineralogy. It is then possible to analyse certain parts of the core in more detail (preparation of powder from rock samples) using the XRD-XRF benchtop analyser, to gain more precise chemical and mineralogical information.

What are the main advantages of the Modulab and what’s innovative about it?

It enables us to bring the analysis phase directly into the field and has three major strengths:

- On-Site Analysis with results in Real time: autonomous instruments deployable in remote locations or in the lab

- Plug & Play: addition of high-tech sensors on demand and connection and automated calibration of sensors

- Data Processing in a Unified Repository: which is the next module of the SOLSA Expert System that we will see tomorrow.

The analytical machines in the Modulab do not claim to be the most accurate on the market, compared to laboratory equipment. Their main strength is that they can travel and efficiently analyse many samples directly onsite. This increases the representativity by feeding the sampling selection process by providing sufficient chemical and mineralogical data to make decisions. You can adapt the sampling strategy directly on site based on the almost-instantaneous results. Obviously, certain machines in the laboratory are highly sensitive and can provide more accurate results, but they require a specific sample preparation and environment of operation that can’t be replicated in the field. Analysis in the field shortens the lead time between the sample collection and the results from several days or weeks to just one hour! Moreover, combining data coming from the different sensors in a unique software allows to increase the confidence of the expertise; this approach is often not done in laboratory setting due to the lack of compatibility between instruments. This is a unique characteristic of the Modulab.

The Modulab is unique because it’s mobile, robust, has a low consumption, can analyse on site and the results are almost instantaneously available

So what if we didn’t have the Modulab here, what would a typical analysis procedure look like?

If we’d followed a traditional analytical procedure, the field work would have enabled core recovery, but the samples would have been sent off for analysis and, only when the results come back (sometimes taking several weeks), would we be able to interpret the site data. If any additional samples were needed to complete the picture, we would be obliged to schedule an additional field campaign.

The Modulab is flexible, mobile, saves precious time and money, provides high volumes of quality data that can be used for on-site decision making. Thanks to the Combined Analysis strategy, the interpretation of the data by the operator and software routines is greatly simplified! The instruments allow a new exploration approach all in real time: 1. Retrieving the sample, 2. Analysis, 3. Interpretation, and 4. Correction/adaptation of the exploration plan!

It is a real “decision-assistance” tool.

Day 3 slide show

Day 4 – software & database: getting the results directly onsite in real time

Interview with Ankur Sinhar (Uni Trento) and Christophe Bessin (Eramet Ideas)

Can you explain what you’re doing inside the Modulab in front of the computer and two screens?

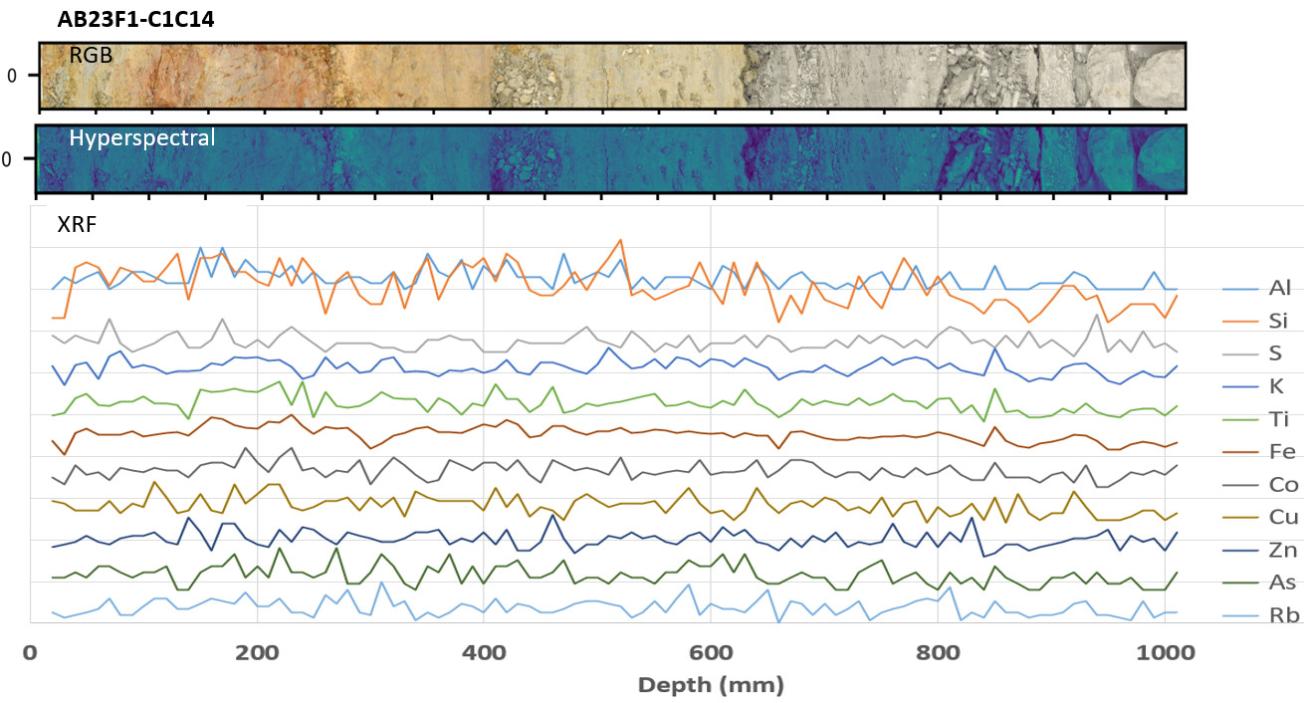

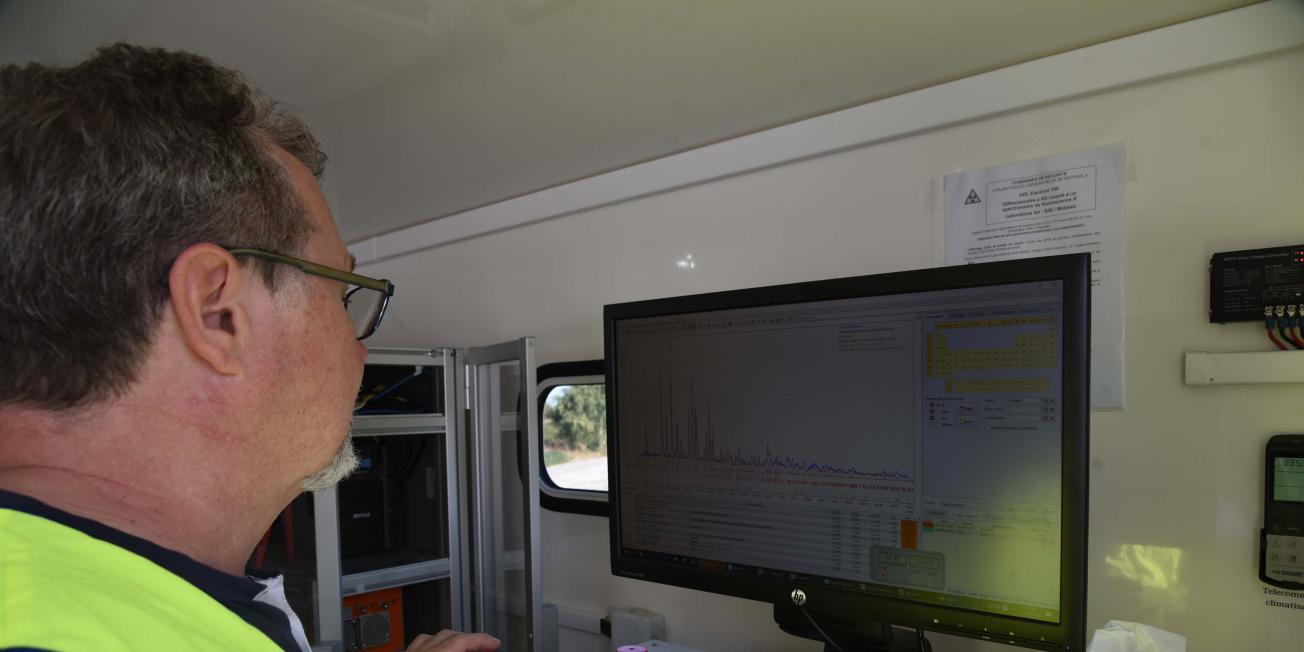

We have just done the data processing of the drill cores and samples, and now we’re visualising them on screen. The main advantage with the Modulab is the quick display of results: the average time between data acquisition and visualization is less than 30 minutes! This is a major breakthrough compared to the time spent waiting for results after sending samples off to a laboratory.

The data processing is done in a unified repository using specialized mineralogical databases and decision-making software. Data are accessible via the cloud, compatible & interoperable.

And was this useful in the field tests here at Abbaretz?

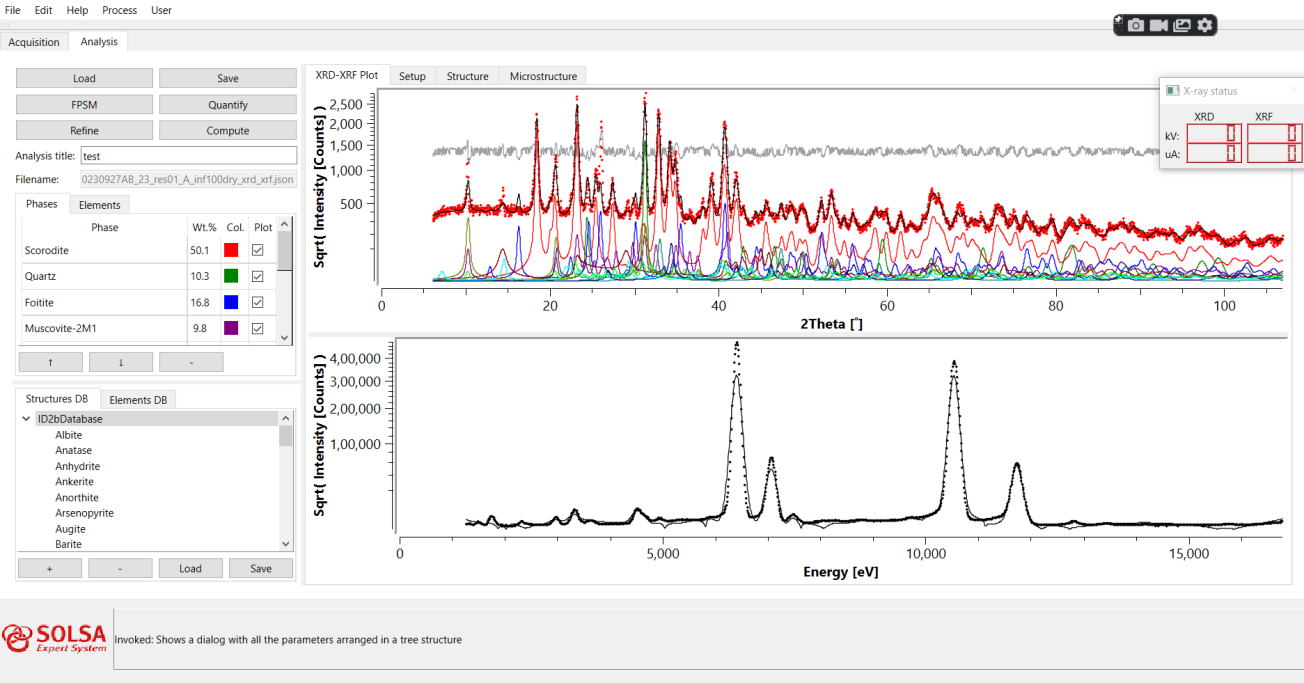

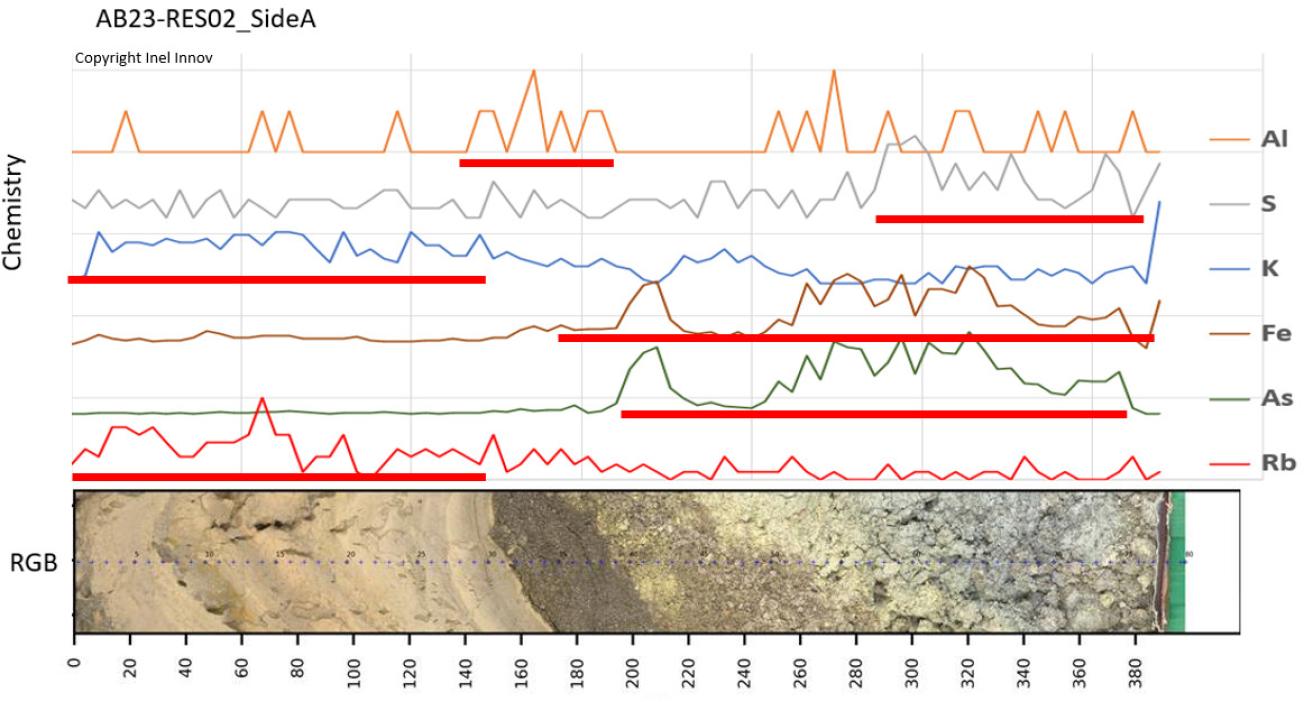

Absolutely! We gathered rapid information of sufficient quality to be able to interpret the chemical, mineralogical and morphological data. From this, we were able to do a preliminary diagnostic interpretation, tailored to the aims of the field campaign. In our specific context, we are focusing on where the source of the arsenic is coming from, in order to monitor and predict potential environmental pollution. Combining the morphological, chemical and mineralogical variations on the screen allow to have a global knowledge of the material and to follow its evolution in order to better understand the process involved. Here, we can see a clear arsenic spike that corresponds to the blue-green horizons correlated to the presence of clays and phases of sulphate and/or arsenate. To have an in-depth knowledge of this remarkable level we sampled and analysed using the combined XRF-XRD benchtop analyser, which confirmed the high proportions of arsenic and, above all, enabled the identification and quantification the carrier phase that is scorodite.

Do you have an anecdote or unexpected story to tell of what happened this week in the field?

We learned an unexpected advantage of having the Modulab on site, which is the complementarity of analysing drill cores and, depending on the results, doing extra sampling by hand at outcrops.

Here we’re looking for the root cause of the arsenic pollution, so we need to understand why some rock formations have high levels and others don’t. We were confronted with a missing link: the drill core data were not providing the answers we needed on the origin of the arsenic. So, we concluded that the drill cores did not intersect the rock formations containing the arsenic source. Consequently, the team went looking for additional samples on foot. They noticed that the minerals releasing arsenic have a particular green-blue colouring, so they explored the surrounding outcrops and took some samples for a second round of analyses in the Modulab. Getting the results back and modelling them in real time increased considerably the understanding of the site, which is a real benefit. We determined that the arsenic is located in the lighter coloured horizons with blue-green hints. This sample shows a distinct arsenic spike on the screen associated to the As-bearing mineral scorodite.

The main advantage with the Modulab is the quick display of results: the average time between data acquisition and visualization is less than 30 minutes!

Interview with Valérie Guerin, BRGM, in charge of environmental monitoring of the Abbaretz site

What is your task here at the old Abbaretz mine?

I work in BRGM’s Department for Mine Safety and Risk Prevention, where we undertake the management of former French mines on behalf of the State. The challenge is to understand the site in order to design the best-adapted management plan. At Abbaretz, we’re facing the problem of Acid Mine Drainage (AMD), which is the outflow of acid waters from the tailings due to the oxidation of sulphide minerals, potentially harmful to the environment. Understanding the quantities at the source is vital to predicting the AMD duration and then be able to design the appropriate remediation plan.

Have you seen the benefit of having the SOLSA Expert System onsite?

It’s extremely beneficial from an environmental monitoring point of view because the coupling of 1) having access to high-quality cores (sonic drilling) with 2) being able to carry out real-time sample analysis (Modulab) enables us to reconstruct the history of mining deposits and therefore estimate:

- the pollution levels,

- the pollution-bearing phases, and thus:

- the potential of acid mine drainage related to the presence of sulphides,

- the mobility of the trace elements according to their mineralogical characteristics.

The Modulab brings the added value of enabling a more precise mineralogical approach which in turn helps build a more robust management plan for trace element pollution.

Day 4 slide show

Day 5 – wrap up and conclusions

Interview with Thomas Riegler, Coordinator of the SOLSA-DEM’UP project, Eramet Ideas

Can you sum up the field tests of the SOLSA Expert System over the past days and what has been discovered?

Well, we’re a step closer to achieving what was not possible before. We have demonstrated under real-life conditions the system’s capability to explore the site by 1) drilling and high-quality sample recovery, through to 2) sample analysis and 3) obtaining results on the rock chemistry and mineralogy in real time. The Modulab allows us to analyse the various samples and get a more complete picture of what is going on. In terms of environmental monitoring of this particular site, the results enable us to trace the main contaminant –arsenic, and follow its mobilization. It is a wonderful tool to orientate your sampling campaign.

Can you summarise the main advantages of the system?

One of the unique capabilities is to be able to do coupled analysis in the Modulab: mineralogical composition AND geochemical composition. This brings a huge added value, with combined analysis, in real time, directly on site. It allows for a better understanding of As mobility and about the conditions controlling the mobility of As in the tailing stacks at Abbaretz.

The speed element is important: getting the results on site, even in remote locations. Our solution avoids sending samples off for analysis bringing delays, extra shipment cost, possible loss, etc. The time gained is absolutely massive. And let’s not forget that the system is applicable in a wide range of contexts (mining, contaminated sites and land, etc.).

The SOLSA Expert System speeds up facilitates on-the-spot decision making

A word of conclusion?

The SOLSA Expert System is all about quick and on-site quantitative data acquisition. It brings the added value of being able -directly on site, to collect a sample, run it through the Modulab for analysis, and then adapt your strategy depending on the real-time results. The system is a breakthrough innovation whether applied to an exploration campaign or environmental monitoring. It speeds up and facilitates on-the-spot decision making.

Day 5 slide show

The outcomes of the SOLSA Expert System field tests will play a pivotal role in shaping the future of sustainable drilling technologies and on-site real-time combined analysis.

A big thanks to the entire SOLSA-DEM’UP team on site for their hard work, enthusiasm and warm welcome.

Special thanks to EIT Raw Materials for funding the project

SOLSA Expert System

.