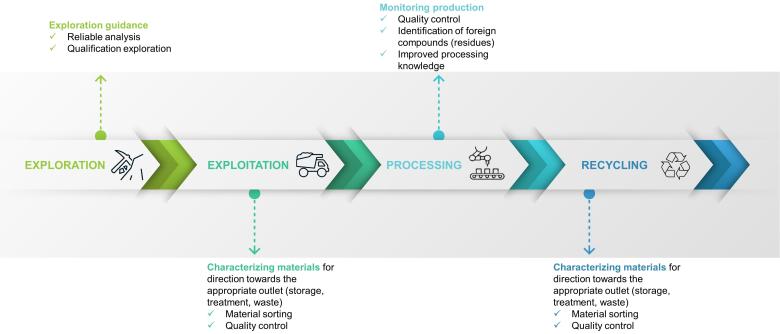

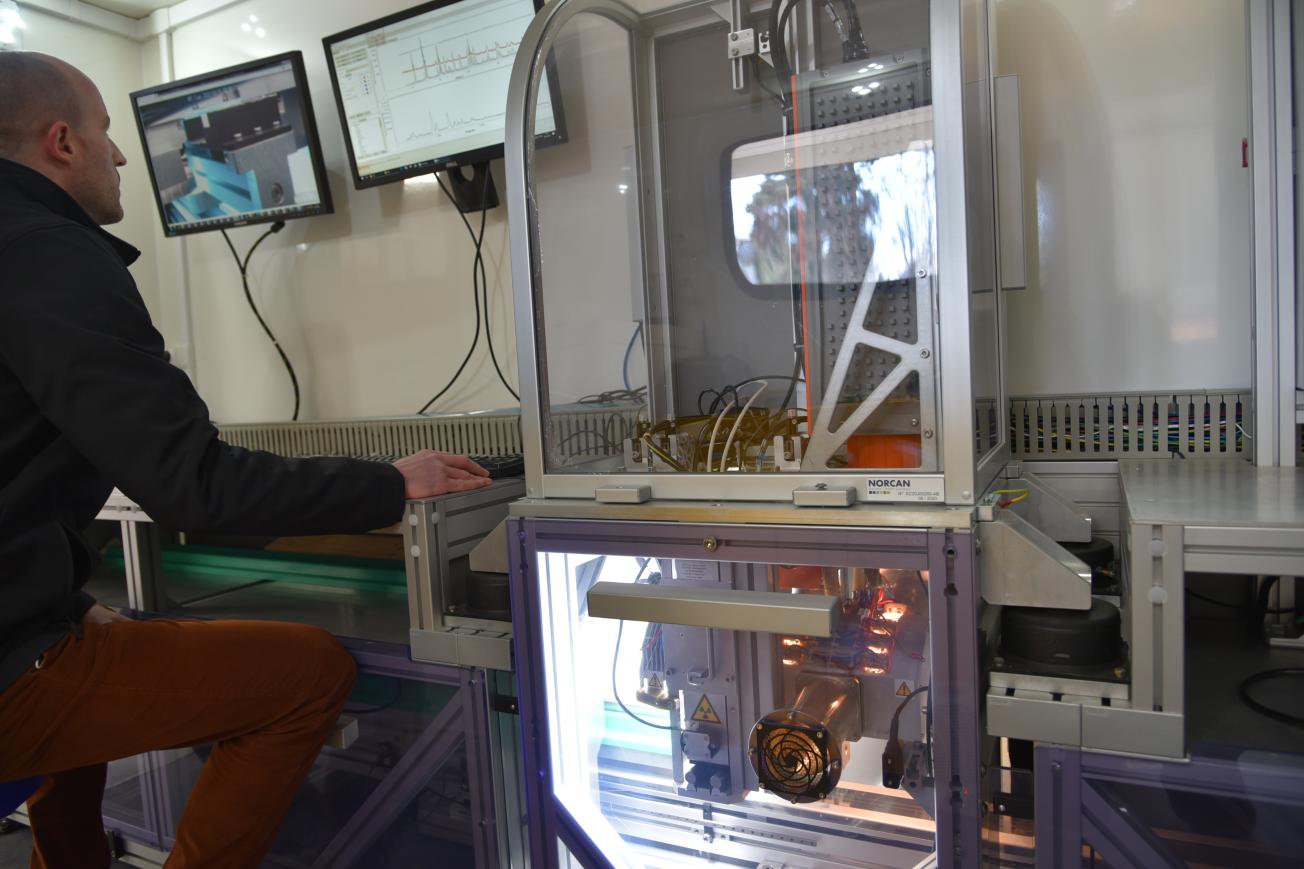

The analytical equipment is designed to work together or independently, and can be combined on-site with the mobile sonic drill rig.

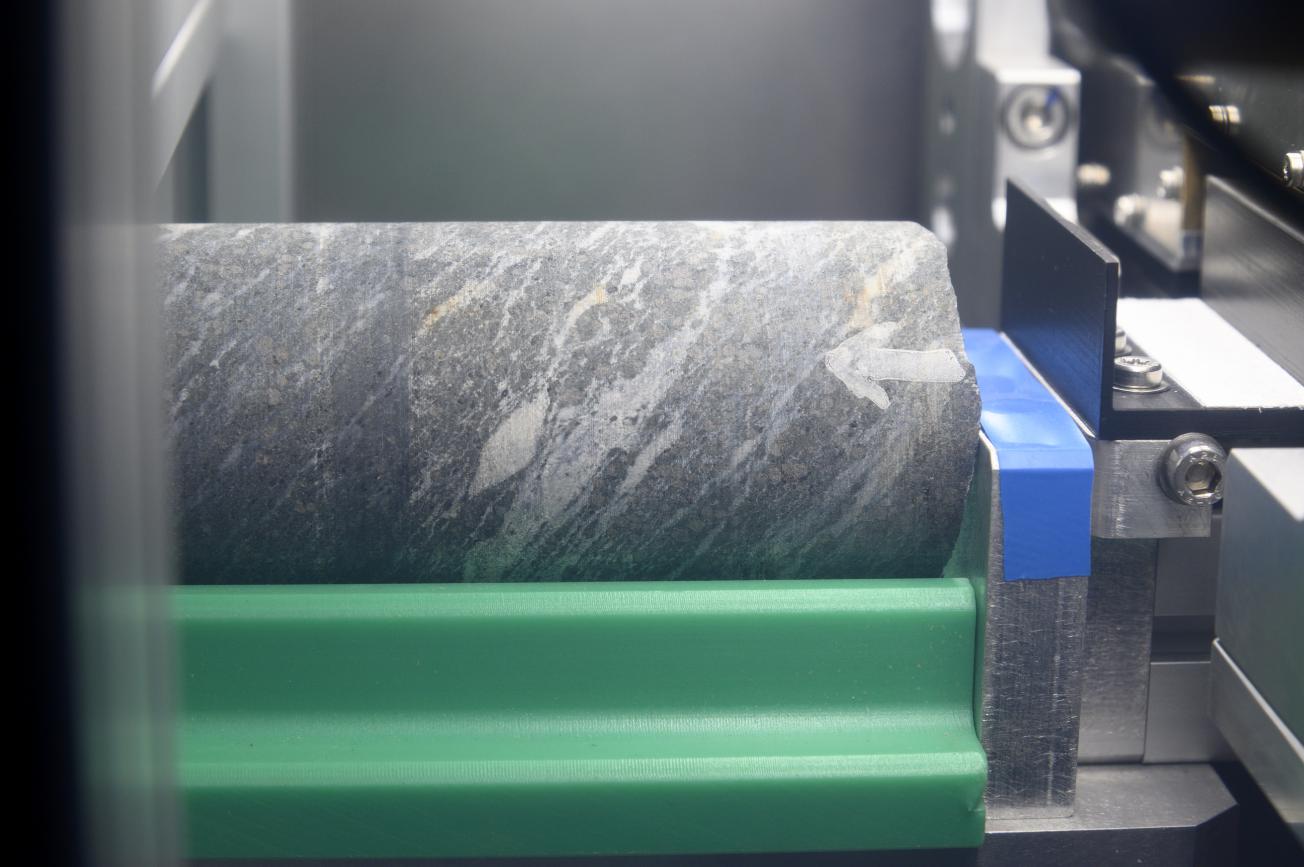

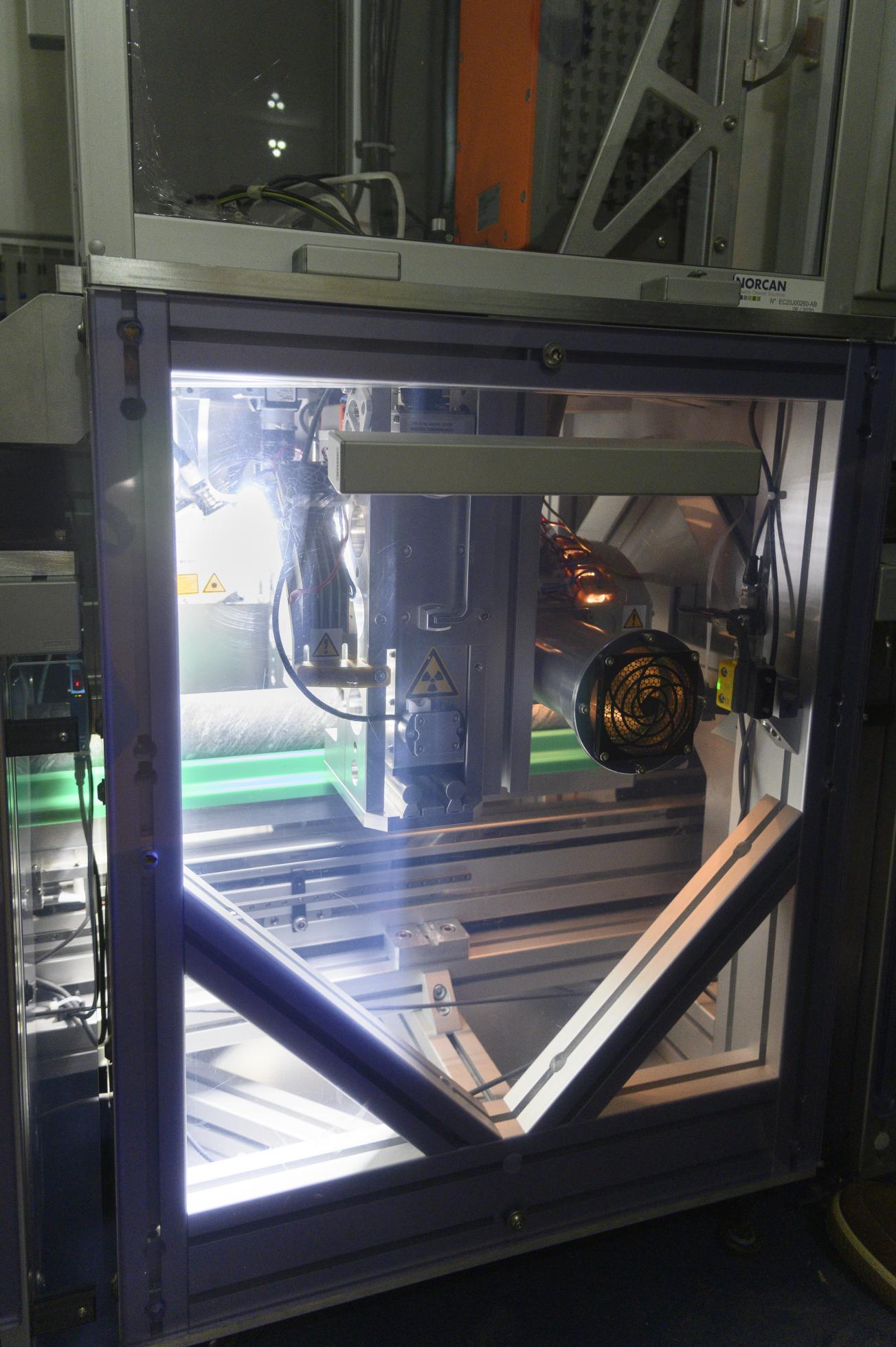

1. The ScanLab, a multi-sensor core scanner for morphological, chemical and mineralogical continuous analyses

The TerrAnalytiX ScanLab

© Smidesang & Lyng

Detailed description

On-line, on-site and real-time core scanner for mineral, geochemical

and morphological characterization

The ScanLab combines for the first time non-destructive and fast profilometric, RGB, X-ray fluorescence and hyperspectral measurements to provide detailed morphological, geochemical and mineralogical information on uncut drill cores, lose or chip materials. Real-time data integration (data fusion) aquired from different sources into a unique metric referential forming a mega-file with a 30-μm highresolution delivers structured, reliable and ready-to-process data.

Automated processing and visualization of integrated data with a decision-making software based on pre-defined key geological features allow to identify the Regions Of Interest (ROIs) and to provide geologists real-time access to geological data.

Take a trip along the ScanLab core scanner conveyorbelt!

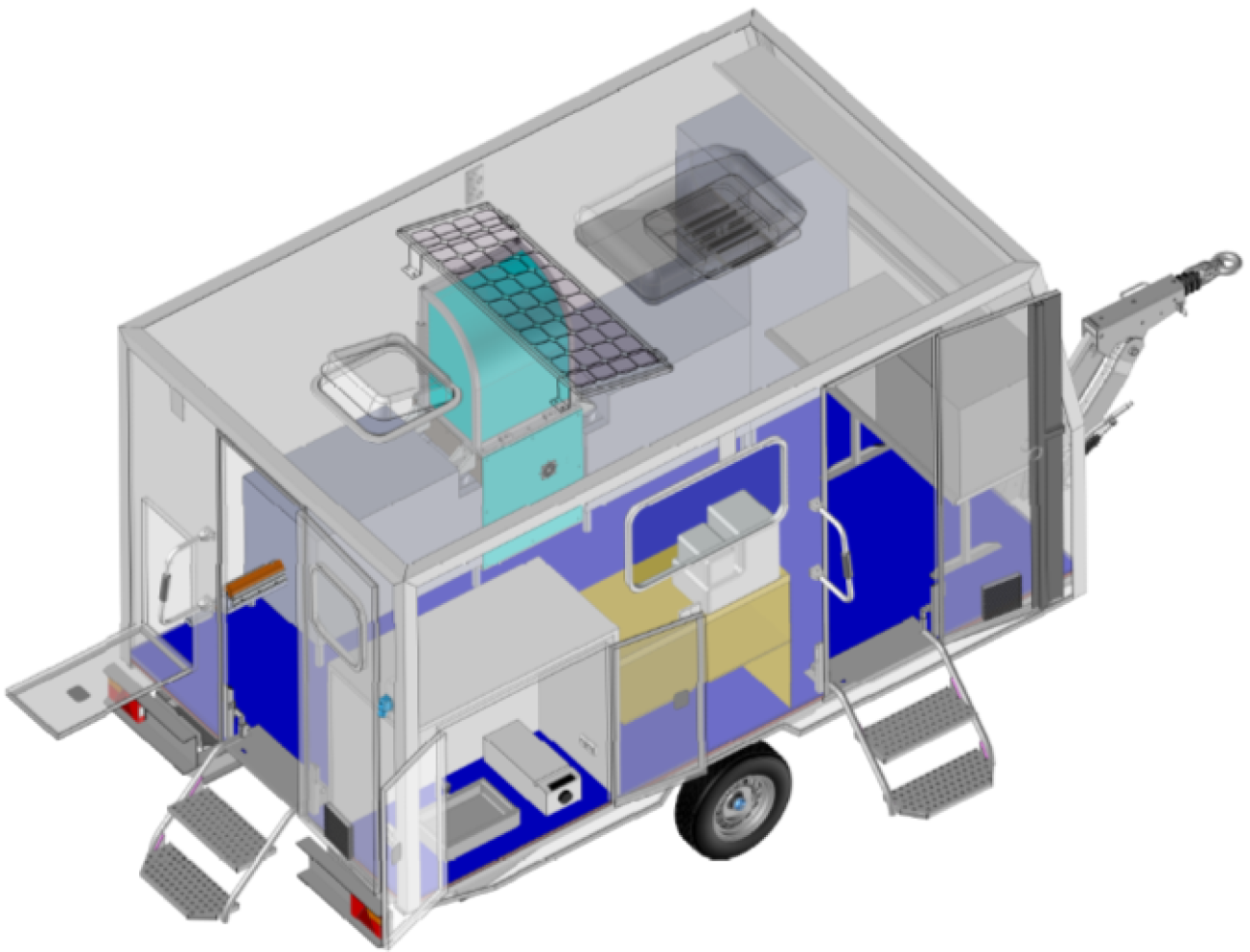

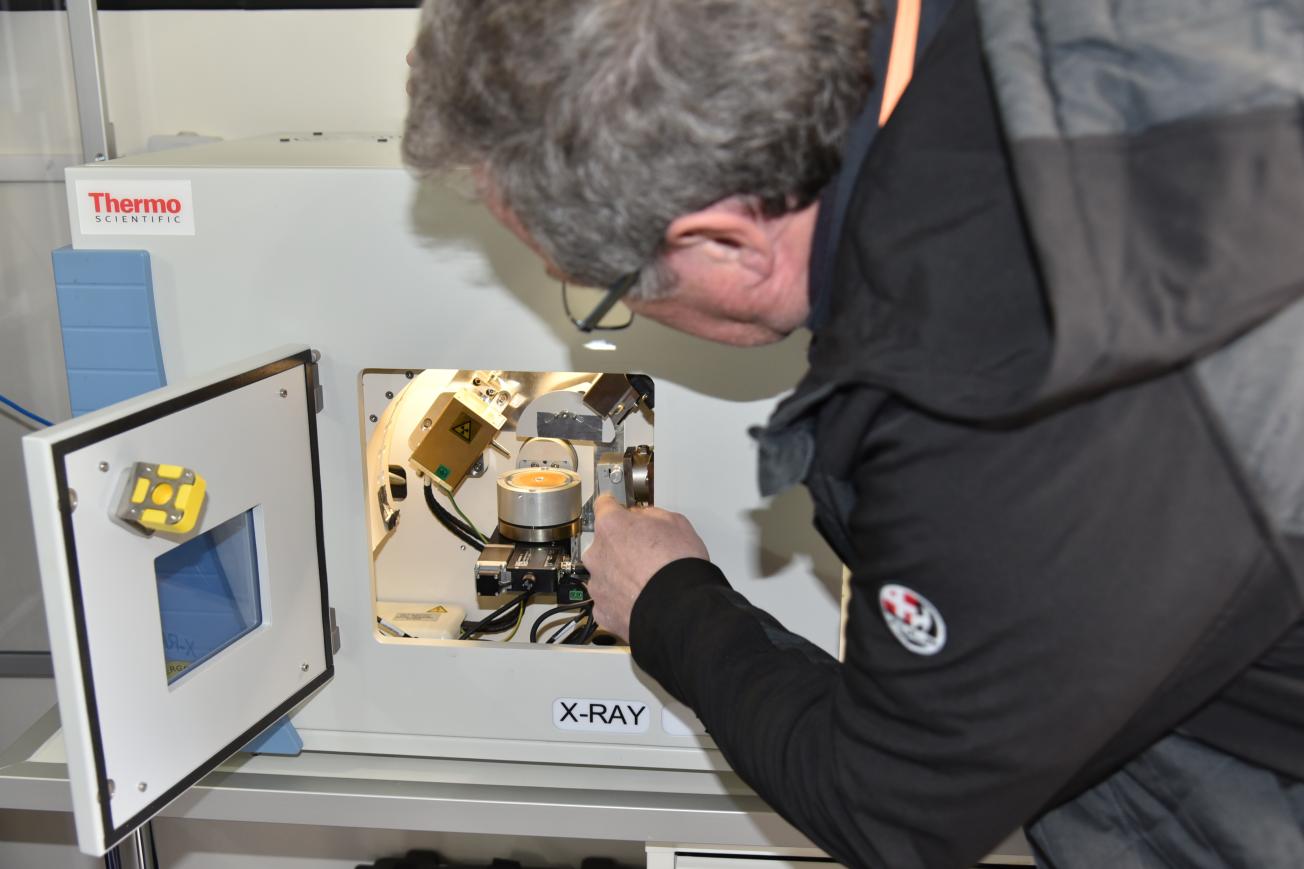

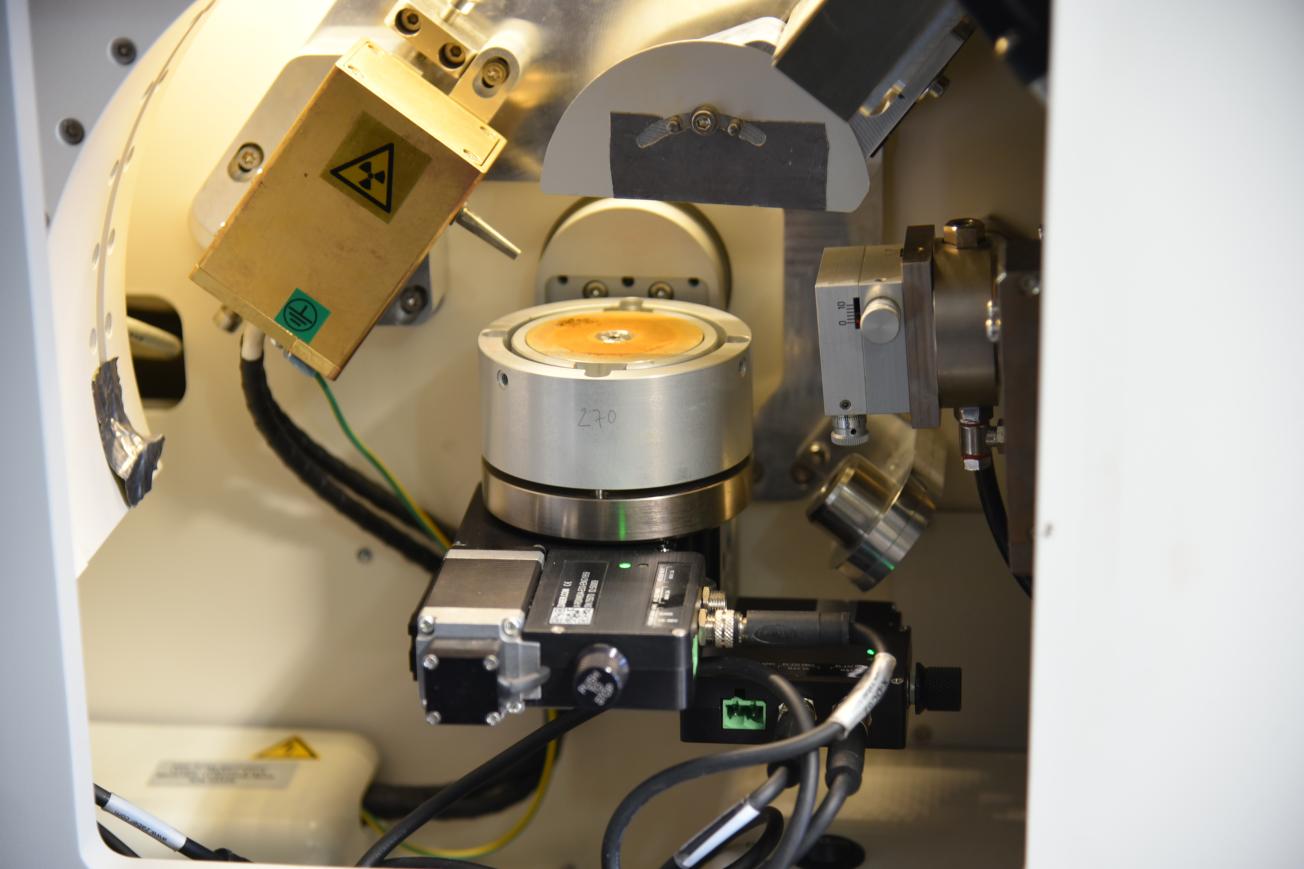

2. The VanLab, a compact XRD-XRF analyser for chemical and mineralgical discrete analyses

The TerrAnalytiX VanLab

© Smidesang & Lyng

Detailed description

On-site benchtop analyser for global chemical & mineralogical quantification

Fast data flow is achieved with two separated instruments sharing the same sample holder system and working in coordination and synergy: the Discrete Combined Analytical X-ray (DCAX) and Discrete Combined Analytical Raman (DCAR). The first is a combined XRD-XRF instrument for simultaneous acquisition and the second is a special Raman spectrometer.

The VanLab can be :

- coupled with the ScanLab and used to investigate more in-depth the Regions Of Interest (ROIs);

- deployed independently on-site for chemical and mineralogical characterization using combined XRF-XRD analyses.

In the first case, representative samples are extracted for analysis by XRD-XRF-Raman based on the results of the phase and elemental map obtained from core scanning, thus giving a quantitative more accurate analysis of the mineralogical and chemical content.

The data workflow is automated allowing data acquisition, processing and visualization in real-time (20 min/sample) without compromising accuracy. Even complex phases like clay minerals can be quantified accurately.

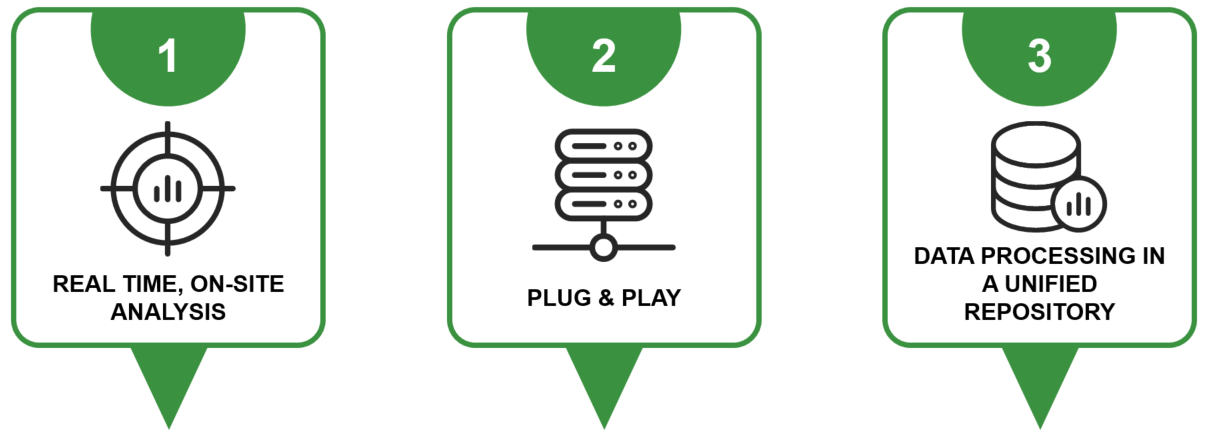

Together, the MODULAB brings 3 major strengths to answer your needs

MODULAB 3 strengths

© SOLSA

1. Real-time, on-site analysis

- Autonomous instruments deployable in remote locations as well as in a factory or laboratory

- Average time between acquisition and visualization of results < 30 min (varies according to the number and type of sensors)

2. Plug & play

- Addition of high-tech sensors on demand

- Connection and automated calibration of sensors

3. Data processing in a unified repository

- Specialized mineralogical databases

- Decision-making software using innovative digital approaches (AI)

- Data accessible via a cloud

- Data compatible & interoperable with user data

Meet the Modulab and discover it's analytical capacities with our 360° Virtual Tour

Slide show of the MODULAB in action

For further information and tailored solutions

TerrAnalytiX

Saint-Denis-en-Val

45560 Centre-Val-de-Loire

France