The software developed for SOLSA is part of the digital transformation concept applied to the raw materials sector, where the basic data consist of samples, which are by definition fragmentary. Processing such data involves data science, automation, geometallurgy and other 4.0 techniques.

The software and database aim at driving the instruments, providing and interpreting diverse types of data provided by the upstream sonic drilling and MODULAB analysis stages, and combining all information to achieve an operational intelligence system easily usable by end-user operators who do not necessarily have expertise in spectral analysis.

New generation software

SOLSA uses a new generation software, and advanced version of traditional software. This will help improve data analysis and speed up treatment decisions, whilst attaining high accuracy.

-

Advanced offline mode analysis

SOLSA has a powerful offline mode that can be used when internet connection is unavailable. This means you'll never have to wait for online connectivity again!

-

Live update with Internet connection

Connecting SOLSA online will allow you to send your drill core samples for remote processing, allowing more advanced treatments like AI and complex algorithms that could be too computationally expensive on your local machine

Data analysis made easy

Get insights on your data with our cloud-based software database, no installation required.

-

Connecting data across industries

We're collecting and indexing millions of sources to help you find correlations in your data across industries

-

Mining big data for insights

Use the power of SOLSA's big data mining to gain insights into your drillings, mines or anything else that needs analysing and uncover patterns from a million rows of numbers in seconds!

A combination of techniques

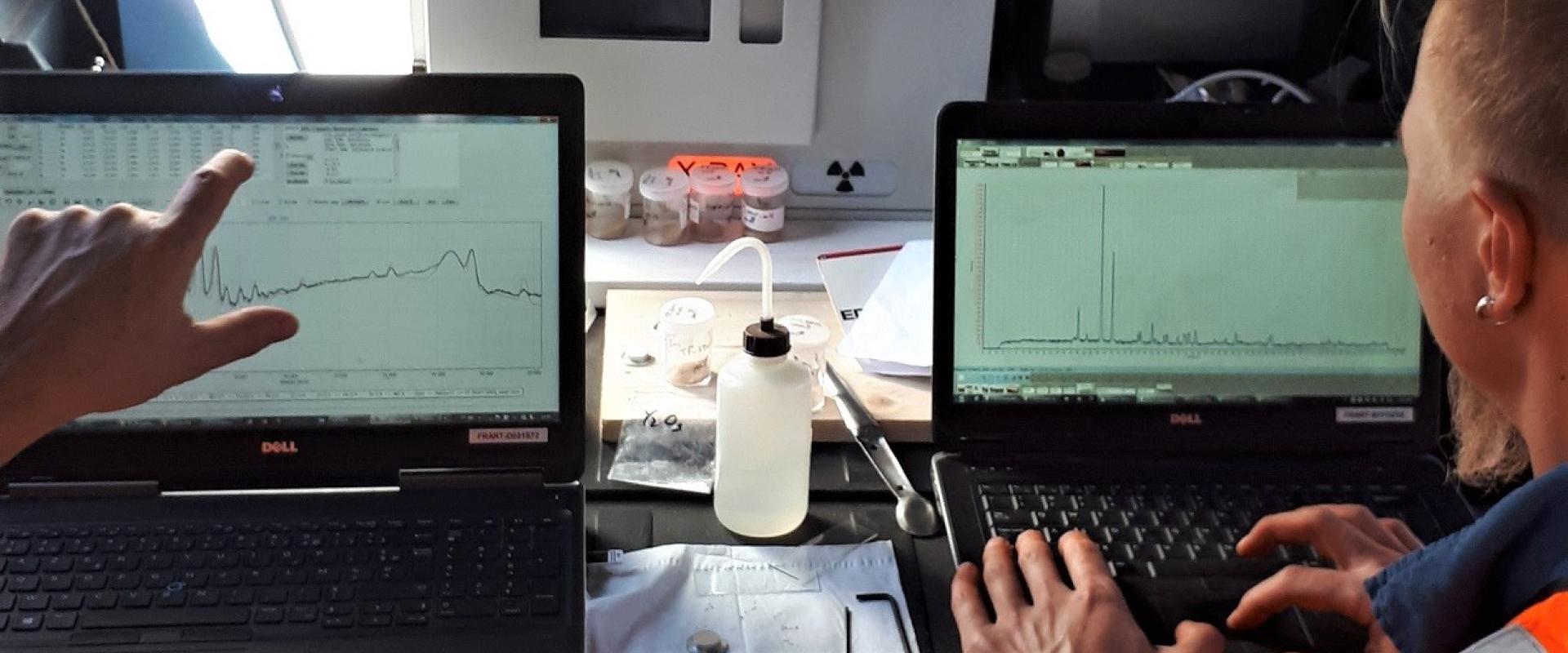

Application case: discrete analysis

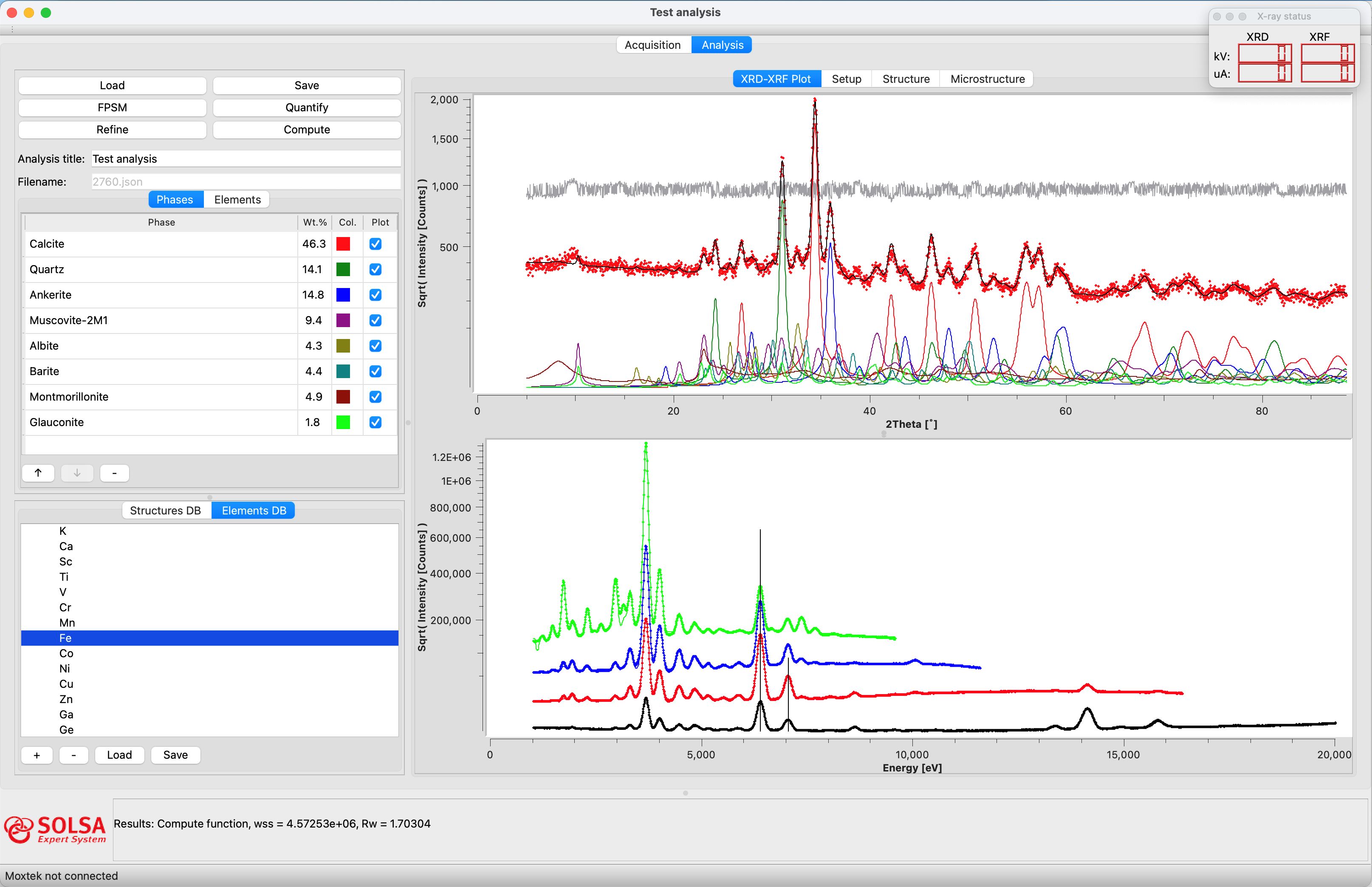

All data acquired by the MODULAB discrete analysis system (XRD-XRF-Raman) are processed using an advanced combined method in the same unique software-interface. Data after acquisition is automatically processed to obtain the accurate quantitative mineralogical and chemical content of the sample.

The results are transferred to the database used by the global online interface to revise and parse geolocalised results.

Combined analysis interface, XRD refined data on top, XRF spectra fitted on the bottom. Results are displayed in the left panel.

© SOLSA

State-of-the-art approaches

Application case: discrete analysis

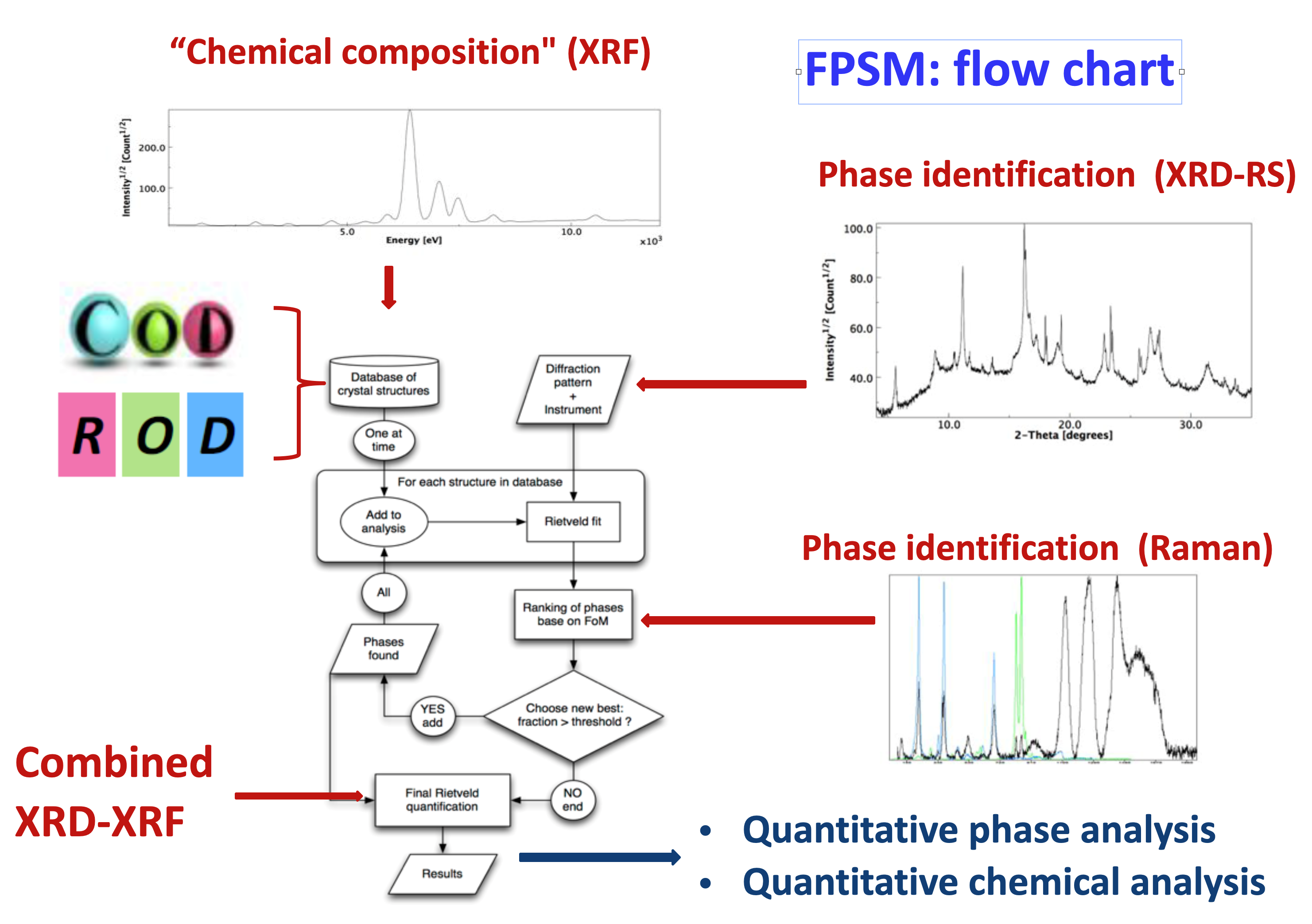

The combined analysis method is based on two powerful new approaches using state-of-the-art methodology.

- The first, Full Pattern Search Match (FPSM), searches for phases and chemical elements (Lutterotti et al., 2019), and is used in combination with Raman input (see figure).

- The second is used for final quantification of mineralogical crystal structure and chemical elements. It combines a Rietveld method for XRD fitting with a fundamental approach for XRF simulation in a unique algorithm refining both data simultaneously with a unique sample description (Bortolotti et al., 2017).

This permits the most accurate description of the physics behind and eliminates approximations used in separated approaches. It can also estimate light element, such as O, C, etc., which are not quantifiable by a standard XRF in air or under gas.

The FPSM method combining Raman input

© SOLSA

Customization and modularity

- Each instrument is controlled by its own software, which allows them to work alone or together, leaving the operator the choice of the best configuration according to the desired objective.

- Possibility to expand the scope of analysis by adding other types of sensors or technical modules

- The graphical user interface can be customized to provide interpreted data according to the end user’s needs.

Safety

- Data is stored in a secure database located on a central cloud or on a customer’s own platform. It can be easily connected to existing drill hole database already in place at the operating company.

- The data transfer is encrypted and secure and can take place online or offline.

- The data backup is automatic or programmed on network or platform.